In any electrical installation, choosing the right cable is vital—not only for reliable performance, but also for safety and compliance. Flexible cables are widely used across domestic, commercial, and industrial applications due to their versatility and ease of use. But not all flexible cables are the same. A key decision you’ll face is whether to use PVC (Polyvinyl Chloride) insulated flexible cable or LSF (Low Smoke and Fume) flexible cable.

Both options have distinct characteristics and are suited to different environments. In this blog, we’ll explain the differences between the two, explore where each type is best used, and help you determine which is the right choice for your project.

What is Flexible Cable?

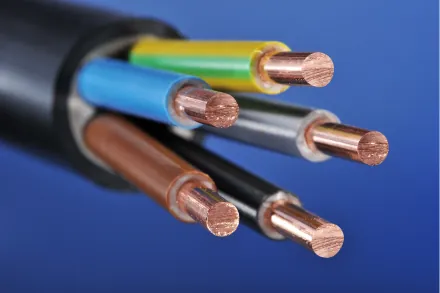

Flexible cable is a type of electrical wiring designed to bend easily without sustaining damage. It typically features stranded copper conductors that allow movement, combined with an insulating and sheathing material that protects the core and maintains electrical integrity.

These cables are ideal for situations where rigid wiring would be impractical or unsafe. Whether you’re running cables through tight corners, connecting portable equipment, or wiring within conduit, flexible cable is a convenient solution that adapts to the physical constraints of the environment.

Key Features and Benefits

- Excellent Flexibility: Both PVC and LSF cables offer excellent flexibility thanks to their stranded copper conductors, making them ideal for installations in confined spaces or moving parts.

- Durable Sheathing: Protective outer layers help resist mechanical wear and prevent damage from abrasion or impact during installation.

- Available in Various Sizes and Core Counts: It is available in a range of conductor sizes and core configurations, suitable for lighting, appliances, control panels, and more.

- Option for Enhanced Safety: LSF cables are engineered for environments where reducing smoke and gas in the event of a fire is a priority, helping protect people and equipment.

Types of Flexible Cable: PVC and LSF explained

There are two common types of flexible cable based on their insulation and sheathing materials:

- PVC Flexible Cable: The standard and most widely used option, PVC flexible cable is made using polyvinyl chloride. It offers good electrical insulation, mechanical protection, and flexibility, all at an affordable price point.

- LSF Flexible Cable: LSF, or Low Smoke and Fume cable, is designed to reduce the emission of smoke and toxic gases when exposed to fire. This makes it a safer choice for environments where maintaining visibility and reducing harmful fumes is critical in the event of a fire.

| Feature | PVC | LSF |

| Toxicity | Can release toxic gases when burnt | Lower toxicity, safer in enclosed spaces |

| Fire Safety | Standard compliance for general use | Preferred in public buildings and escape routes |

| Cost | Lower upfront cost, can be used in a variety of settings without breaking the bank | Slightly higher price but the added safety features pay for themselves |

| Flexibility | High | High |

| Suitability | General indoor environments | Enclosed spaces or where fire safety is critical |

Explore Our Flexible Cable Range

Here are some popular options available in both PVC and LSF flexible cables. You can click each product for detailed specifications and to find out more information.

Our sizes range from 2 Core 0.5mm all the way to 5 Core 1.5mm, with the option of black or white in certain sizes.

A popular option is the 3183Y0.75BLK | 0.75mm 3 Core PVC Round Flexible Cable, Black (100m).

This 100 m drum of 3183Y 0.75 mm² 3-core PVC round flexible cable features finely stranded copper conductors and durable PVC insulation and sheathing. Its flexible design makes it ideal for applications such as washing machines and extension leads, providing reliable ordinary-duty performance.

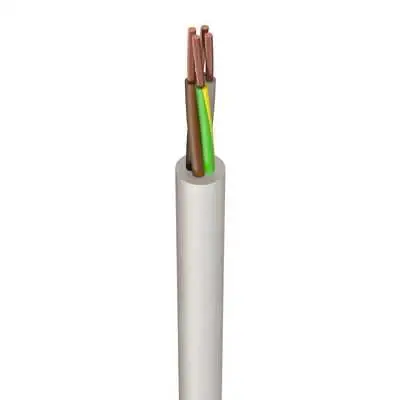

Another option is the 3184B1WHI | 1mm 4 Core Round Flexible LSF Cable, White (100m).

This high-performance 1 mm², 4-core white flexible cable is sheathed in Low Smoke and Fume (LSF) material, ensuring minimal smoke and toxic emissions in the event of a fire—making it ideal for public or enclosed areas like schools, offices, or transport hubs. Available on a convenient 100 m drum, it’s designed for indoor general wiring applications such as pendant lighting or supply leads.

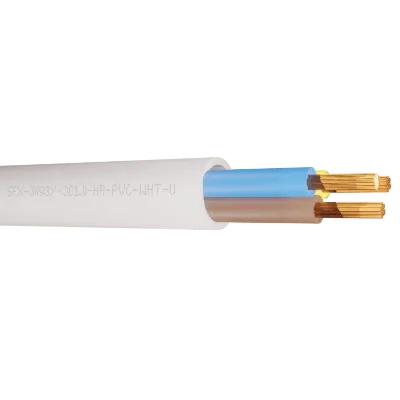

A further option to consider is the Securi-Flex SFX/3093Y-3C-1.0-HR-PVC-WHT-U-100 | Power Cable Flexible 1.0mm 3 Core HR-PVC White (100m).

This 100 m drum of Securi-Flex SFX 3093Y heat-resistant flexible cable features 1.0 mm², 3-core construction and is insulated in HR-PVC for enhanced durability and a higher temperature rating—perfect for applications subject to elevated heat, like kitchen appliances or industrial heating systems. Its sleek white finish ensures discreet integration in modern interiors.

Click ‘Here’ to see our full flexible cable range and see what suits your project.

Applications of Flexible Cable

The settings that these can be used for is varied, these include

- Domestic lighting and power installations

- Commercial fixed wiring

- Temporary site supplies

- Public buildings such as schools, hospitals, and offices

- Portable or handheld electrical equipment

The choice between PVC and LSF generally depends on the risk level of the environment. For example, LSF cables are ideal in areas with high occupancy or limited ventilation to ensure safe evacuation in the case of a fire. Whereas PVC is acceptable in low-risk or well ventilated areas.

Factors to Consider

There are multiple factors to consider when choosing what cable you want for your project/job, below we discuss what these may be.

Regulatory Requirements: Check local building regulations and fire codes. Many public or commercial installations use LSF cable as it is required.

Environmental Conditions: Use LSF in enclosed spaces, areas with poor ventilation, or buildings with high occupancy. PVC is more suited to standard domestic and low-risk environments.

Project Budget: PVC cables are a cheaper option, however if fire safety is a concern or a regulation, LSF is an investment that is worth the money in the long run.

Future Proofing: If the building may undergo future changes, LSF is a safer and more future-compliant choice.

Final Thoughts

Flexible cable remains a core product in modern electrical installations thanks to its ease of use, durability, and adaptability. While both PVC and LSF options offer similar electrical performance and flexibility, the choice between the two often comes down to safety requirements.

For standard domestic wiring, PVC cable continues to offer a cost-effective and reliable solution. However, in commercial premises, public buildings, or any environment where fire safety is paramount, LSF cable is the smart, compliant, and responsible choice.

Understanding the differences between these two types of flexible cable helps ensure your installation not only performs well, but also meets modern safety standards and regulatory expectations.